Meet us at Hello Tomorrow, Paris

We’re thrilled to announce we’ve been named a Deep Tech Pioneer by Hello Tomorrow!

From thousands of applications their experts saw real potential in our solution.

Come and meet us at the Hello Tomorrow Global Summit in March 2024, the cornerstone event dedicated to celebrating and accelerating deep tech innovation: connecting key people bringing solutions from lab to market and strengthening the deep tech investment network.

Don’t miss out!

Find more info here.

Spectricity Announces Collaboration with Qualcomm to Bring Spectral Imaging to Next Generation Smartphones, Unlocking Accurate Color and Seeing Beyond What’s Visible.

Both companies agree on the development of a native reference design for use with premium Snapdragon® mobile platforms.

Barcelona, Spain, February 26, 2024 — Spectricity announces a collaboration with Qualcomm Technologies, Inc. for Spectricity to develop native reference design support for use with premium Snapdragon® mobile platforms and Spectricity’s spectral image sensor products.

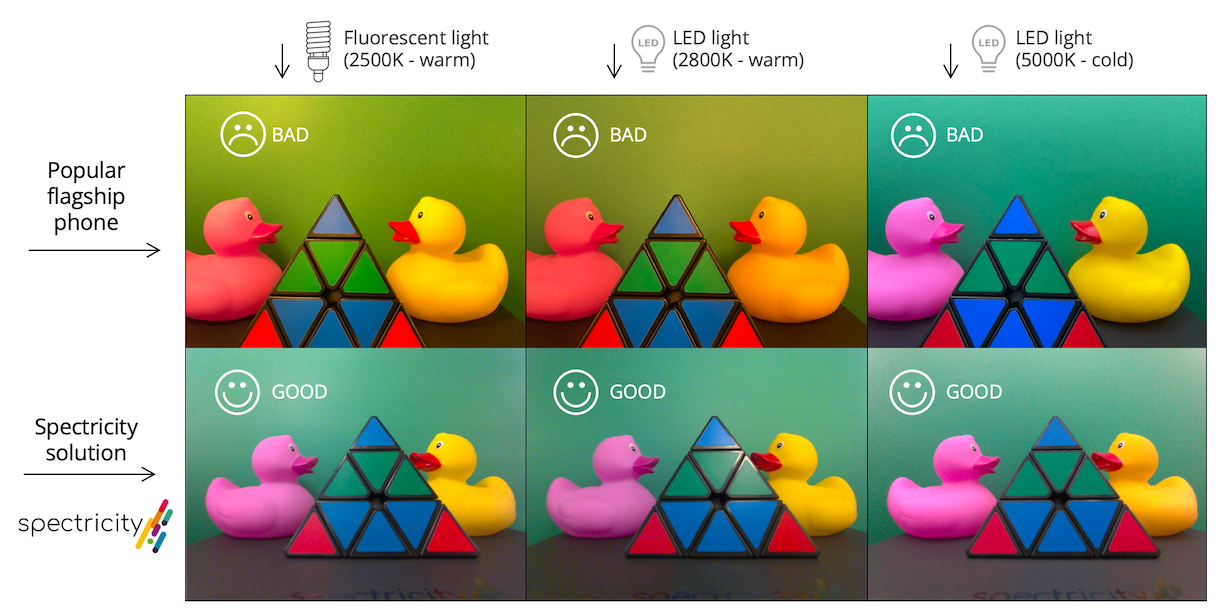

The collaboration will allow for a faster, more efficient implementation for OEMs to integrate spectral imaging in their mobile devices. This in turn can bring significant improvements for camera AWB (automatic white balancing) performance, resulting in more accurate and more pleasing photography, including portraits with accurate skin tone. New applications including e-commerce cosmetics, color picking, as well as skin health analysis are also enabled.

“Qualcomm Technologies is committed to delivering revolutionary image capabilities in our premium mobile platforms to consumers”, said Judd Heape, VP of Product Management at Qualcomm Technologies, Inc. “By collaborating with Spectricity, we can enable these cutting-edge technologies to offer advanced spectral image sensor integrations for extraordinary camera experiences.”

Glenn Vandevoorde, CEO of Spectricity: “We are committed to bringing spectral imaging to smartphones. Our collaboration with Qualcomm Technologies., is a critical step in enabling OEMs to build better cameras for their mobile products, and new, differentiated applications that will improve our daily life, including health. We’re excited to enable this for use on the world's most popular mobile SoC platform.”

About spectral imaging

Spectricity’s unique and patented CMOS multispectral imaging technology extends the paradigm of RGB 3-color filters to 16 or more filters. It allows the measurement of spectral signatures of light for each pixel, to extract properties about the light source or objects in the scene. This in turn enables better white point measurement, or extraction of skin biomarkers such as blood volume of melanin.

Spectricity’s S1 is the world's first truly-miniature spectral camera module for mobile devices, leveraging Spectricity’s CMOS high-volume supply chain, as well as its spectral imaging software IP. The technology and the products powered by it are the fruit of more than 15 years of research and development.

Availability

An evaluation and software development kit featuring compatibility with Spectricity’s S1 spectral image sensor is expected to be available from Spectricity this year.

Snapdragon is a trademark or registered trademark of Qualcomm Incorporated. Snapdragon is a product of Qualcomm Technologies, Inc. and/or its subsidiaries.

About Spectricity

Spectricity, a Belgium-based fabless company founded in 2018, stands at the forefront of spectral sensing solutions crafted with advanced CMOS technologies. Fueled by venture capital and an exclusively-licensed patent portfolio from imec, a global leader in nano-electronics and digital technologies, Spectricity pioneers innovations designed for high-volume production and integration into consumer and mobile devices.

With a commitment to sensing beyond the visible, Spectricity's vision is to enhance life through unparalleled spectral information, anytime, anywhere. Its mission revolves around enabling the widespread adoption of spectral imaging by seamlessly integrating miniaturized sensing solutions. Spectricity's disruptive innovations, protected by a comprehensive collection of patents, strive for accessibility and affordability, opening doors to new possibilities in various consumer markets.

Senior Software Engineer

Location: Belgium, Mechelen

Your main responsibilities will be to

- work together with Computer Vision Engineers to develop processing algorithms for the multispectral cameras

- translate Python prototypes of algorithms into efficient GPU implementations, for mobile and desktop targets

- provide integration and development support in building camera evaluation kits and demonstrators

- review code and coach engineers, who are not programmers but that do use code on a daily basis, towards a better overall quality of infrastructure

Your profile, skills and talents

Ideally you are a creative, self-dependent engineer, highly-motivated to be part of a dynamic team creating new value, continuously and actively seeking better solutions for our problems. Specifically:

- You have a master’s degree in Computer Science, Software Engineering or similar relevant degree, with at least 5 years of relevant experience

- Software engineering, rather than just coding, is your trade. You are comfortable at all levels of abstraction, from architecture planning to debugging of the low-level driver code.

- You master one of the GPGPU technologies: OpenCL, Vulkan Compute, CUDA

- You have experience with media processing pipelines, e.g. GStreamer

- You are not afraid of any programming task needed to get the work done efficiently, whether it required using Python, Go, Matlab, Javascript, Embedded-C or anything around

- You are proficient with Python

- Git and continuous integration and unit tests are the tools you use daily, you can solve any Git-related glitches without problems

- You are comfortable developing for Windows, MacOS and Linux. Android/iOS development history is a plus

- You keep up-to-date with all the newest trends, e.g. Flutter, Mojo, Vulkan, etc.

- You are fluent in English, and have good presentation skills

- You are independent and able to work well autonomously

You will help us be successful when:

- You are a good team player, able to pursue and find compromise through constructive discussion, enthusiasm and skills

- You are result-driven, you have a natural desire to analyze and solve problems and you are self-critical

What Spectricity offers

An exciting experience in a dynamic start-up environment, in a highly-motivated multi-disciplinary team with global exposure in Europe, Asia and US. You will have plenty of opportunities to learn and be creative, to be entrepreneurial and to shape the future of a company.

Glenn Vandevoorde Appointed as CEO of Spectricity, Pioneering Multispectral Imaging Technology

Mechelen, Belgium, January 26, 2024 — Spectricity, an innovator in multispectral imaging technology, has appointed Glenn Vandevoorde as its new Chief Executive Officer. In this role, Glenn will spearhead the company's strategic vision, innovation, and global growth.

As a seasoned tech industry leader, Glenn brings with him a wealth of experience and a track record of transformative success. Glenn’s tenure of various CEO roles in start-ups marks his ability to drive technological advancements in the semiconductor industry. In joining Spectricity, Glenn embarks on a new chapter, poised to lead the company's charge in revolutionizing color imaging through its ground-breaking S1 multispectral camera.

“Leading this visionary team, our mission is to reshape the future of imaging technology. Spectricity is primed to redefine industry standards, and I am honored to guide us towards a future where each pixel narrates a richer and more compelling story.”

- Glenn Vandevoorde, Chief Executive Officer, Spectricity

Glenn's appointment underscores a strategic move as Spectricity enters an exciting new phase of scaling innovation into the market across diverse industries and applications.

“As we enter a new phase of scaling innovation, Glenn’s leadership will play a pivotal role in unlocking the full potential of our multispectral imaging technology across diverse industries and applications. This marks an exciting chapter for Spectricity, and we are confident Glenn will lead us to unprecedented success.”

- Pieter Vorenkamp, Chairman of the Board, Spectricity

Spectricity thanks outgoing CEO Vincent Mouret for his outstanding leadership, directing the company’s research and product development towards this pivotal point of scaling, and releasing its first product into the market.

About Spectricity

Spectricity, a Belgium-based fabless company founded in 2018, stands at the forefront of spectral sensing solutions crafted with advanced CMOS technologies. Fueled by venture capital and an exclusively-licensed patent portfolio from imec, a global leader in nano-electronics and digital technologies, Spectricity pioneers innovations designed for high-volume production and integration into consumer and mobile devices.

With a commitment to sensing beyond the visible, Spectricity's vision is to enhance life through unparalleled spectral information, anytime, anywhere. Its mission revolves around enabling the widespread adoption of spectral imaging by seamlessly integrating miniaturized sensing solutions. Spectricity's disruptive innovations, protected by a comprehensive collection of patents, strive for accessibility and affordability, opening doors to new possibilities in various consumer markets.

See the world in true colors: the first smartphone with multispectral imaging camera makes its global debut at CES

Setting a new benchmark: Spectricity showcases ground-breaking smartphone camera color-matching technology in Las Vegas

Las Vegas, 08-January-2024 - Spectricity, the multispectral imaging solution provider for high-volume and mobile devices, is showcasing its ground-breaking color-matching technology by integrating the first multispectral camera in a smartphone enabling ‘true colors’ on smartphone photos.

- Spectricity has integrated the first multispectral camera in a smartphone

Most of us have been disappointed for some time with our smartphone’s inability to replicate the colors we see, whether in a less-than-perfect picture of an amazing sunset, a poor skin tone, or a mismatched paint sample in the DIY store. This is because smartphones are, in essence, color-blind. They are unable to measure color accurately, due to faulty automatic white balancing that wrongly estimates the white point. These hopelessly random colors will be a thing of the past thanks to Spectricity's multispectral camera.

- True colors all the time, more accurate than the naked eye

Spectricity’s crucial breakthrough has been in its revolutionary “S1” multispectral camera which provides the information necessary for accurate color reproduction. It measures the spectrum of light at 16 wavelengths, in every pixel of the camera. This results in a better white point assessment, which in turn delivers true consistent colors. The camera can also assess colors more accurately than the naked eye giving a true color representation of everything from paint to skin tone. This spectral camera ends all guesswork: colors on smartphone photos will now be true to reality.

- Ready for global breakthrough: this camera can be in any smartphone within 2 years

The delivery of consistent color is an issue recognized and acknowledged in the industry. With photography and camera capability being major drivers for smartphone upgrades, Spectricity’s innovation, which could be in every smartphone within two years, has created a great deal of interest. Currently being tested by almost every major smartphone manufacturer, it is set to have a significant commercial impact on the consumer devices industry.

Its application extends beyond mere aesthetics and far into e-commerce, as the development will allow more accurate assessment of the color of online purchases as well as true skin tone and foundation matching, virtual make-up try-on, accurate lipstick, hair dye matching, and expert advice from your phone.

Furthermore, the application of Spectricity's camera offers far-reaching possibilities in the medical field: for example, online tracking of diseases and providing advice in the area of health and well-being can be improved with it.

Vincent Mouret, CEO of Spectricity, comments: “This camera brings unprecedented color accuracy from laboratory instruments to phones. In most cases, the detected color cannot be distinguished from the true color with the naked eye. Finally, your pictures can be color-consistent, and you can measure and save the true color of objects or skin with your phone. This opens the door to e-commerce for remote personalized cosmetic and retail use cases.”

Jonathan Borremans, CTO of Spectricity adds: “Every smartphone vendor confirms the problem and is struggling to solve the issue. Spectricity is in pole position to deliver the technology to solve the issue. By 2026 these spectral cameras are expected to become mainstream in every phone, as predicted by Yole Development."

Yole Development is a leading market research, technology, and strategy analysis company.

About Spectricity

Spectricity was incorporated in 2018 and is backed by international VCs to bring spectral imaging to mobile devices. With 35 employees, Spectricity has offices in Belgium, the USA, Taipei, Shanghai and Malaysia.

The S1 is currently under evaluation by major smartphone makers. EVKs are available for device manufacturers driving large volumes.

Meet us at CES 2024

Meet us at CES 2024 where we will unveil new premieres in smartphone photography. Book a demo and stay tuned!

Book an appointment at ces2024 @ spectricity.com.

Spectricity introduces true colors with the S1-M camera module for mobile devices

Barcelona, ESP, 27-02-2023 – After introducing the S1, the first sensor to deliver true color through a smartphone camera, Spectricity is now launching a miniature camera module using this cutting-edge technology. This first miniature, mobile device-ready multispectral image sensor, was introduced as a groundbreaking new technology at CES last month. The technology is expected to be adopted in all smartphones coming years.

The new camera module, announced at MWC in Barcelona, integrates the S1 image sensor with an optimized custom miniature lens for spectral imaging in a compact module. The camera module is compatible with mobile devices and smartphone integration thanks to its truly miniature form factor.

Spectricity also announces a partnership with high-volume camera module manufacturer Namuga. Tae Youn Won, the CEO of Namuga says: “We are very excited to work with Spectricity to develop and manufacture the next-level camera module with the S1 sensor. One can’t imagine modern personal life today without sharing daily content. Now, this can be taken to a next level with Spectricity’s improvement in color fidelity combined with Namuga’s experience in manufacturing and module development.”

Spectricity is delighted to partner with Namuga says Vincent Mouret, CEO of Spectricity: “We are excited to work with Namuga’s experienced team for this high-volume product. A high-volume camera module is essential for mobile device integration. We expect the first smartphone models with the S1 to be released as soon as in 2024 and all smartphones to include our technology within the coming years.”

The smartphone camera will no longer be colorblind

The S1 spectral image sensor solves color fidelity issues of smartphone cameras and can measure true color through the spectral signature of an object.

The S1 was recognized as a technology breakthrough at the recent edition of CES: it’s the first truly miniaturized, mass-manufacturable mobile spectral image sensor. At the same time, it captures the full visible and near-infrared range at video rates, required for mobile applications. It’s suited as a companion sensor to the main cameras in a smartphone.

Jonathan Borremans, CTO: “The S1-M camera module marks another phenomenal advance over any multispectral camera on the market. No one to date has managed to fit these specs into a miniature module. The S1-M can be integrated into any mobile device.”

Spectral imaging will fix the poor camera color fidelity of smartphones and consumer devices. Despite all advances in image sensor and camera technology, smartphones still cannot capture true color as they are limited by 3 color channels: red, green, and blue.

Jonathan Borremans: “Essentially, even your high-end smartphone camera is color blind. The S1 uses richer spectral signature data, resulting in much higher color fidelity in your pictures. We’re confident that spectral imaging will become essential in all devices including a camera.”

As part of the smartphone camera of the future, the S1 spectral camera sensor will drive innovation in consumer devices in personalized cosmetics, health and wellness, e-commerce, smart gardening, and authentication.

About Spectricity

Spectricity was incorporated in 2018 and is backed by international VCs to bring spectral imaging to mobile devices. Spectricity has offices in Belgium, the USA, Taipei, and Malaysia.

The S1 is currently under evaluation by major smartphone makers. EVKs are available for device manufacturers driving large volumes.

Spontaneous applications

Send us your resume if you have a background in spectral sensing, and you think you can make a difference in bringing these new technologies to market.

Meet us at MWC 2023 in Barcelona

Meet us at MWC 2023 in Barcelona. Book a meeting at mwc-2023 @ spectricity.com.

World premiere at CES: Spectricity spectral camera brings true colors to smartphone photos

S1 spectral image sensor sets new quality standard in smartphone photography, enables new use cases in e-commerce, cosmetics, authentication...

Las Vegas, 05-January-2023 - At CES 2023, Spectricity introduces the S1, the first miniature, mobile device-ready multispectral image sensor. The first smartphones using the sensor are expected by 2024. Within two years, this technology is expected to be in all smartphones.

The S1 spectral image sensor solves color fidelity issues of smartphone cameras, and can measure true color through the spectral signature of an object.

The S1 is a technology breakthrough: it’s the first truly miniaturized, mass-manufacturable mobile spectral image sensor. At the same time, it captures the full visible and near-infrared range at video rates, required for mobile applications. It’s well suited as a companion sensor to the main cameras in a smartphone.

Jonathan Borremans, CTO Spectricity: "The S1 marks a phenomenal advance over any multispectral imager on the market. No one to date has managed to fit these specs into a miniature chip. The S1 can be integrated into any mobile device."

Currently, Spectricity is sampling the S1 to several smartphone manufacturers to be included in upcoming models.

Vincent Mouret, CEO: "’We are excited to announce this breakthrough; the first ever affordable mobile spectral imager. The release is a key milestone for Spectricity in its ambition to serve smartphone markets, and to pursue our mission to enable mass adoption of spectral sensing in mobile devices. We expect the first smartphone models with the S1 to be released in 2024, and we expect all smartphones to include our technology within the coming years."

"RGB": how spectral imaging brings true colors to smartphones

Spectral imaging will fix poor camera color fidelity of smartphones and consumer devices, a root cause for inaccurate photo colors but also poorly rendered skin colors. This will make camera technology more reliable and more inclusive.

Despite all advances in image sensor and camera technology, smartphones still cannot capture true color. Limited by 3 color channels ("RGB" or red, green, blue), the automatic white balancing (AWB) algorithms often struggle to accurately resolve the white point of a scene correctly. Consequently, they can fail to get the colors right.

Jonathan Borremans, CTO: “Essentially, even your high-end smartphone camera is color blind. The S1 uses richer spectral signature data, resulting in much higher color fidelity in your pictures. We're confident that spectral imaging will become an essential component in all devices that include a camera."

The smartphone camera of the future: The S1 will drive innovation in consumer devices

The S1 will have a significant commercial impact in the consumer devices industry:

- Research shows that photography and camera capability are major drivers for smartphone upgrades

- Personalized cosmetics are already a 40 billion dollar market. Spectral imaging will drive a transition from retail to home, and expert advice from your mobile device, adoption and customer satisfaction in this category.

- Medical applications and use cases will be unlocked with spectral imaging

- E-commerce: better color rendering will support online commerce

- New applications and use cases become possible for authentication (face ID) and even smart gardening

About Spectricity

Spectricity was incorporated in 2018 and is backed by international VCs to bring spectral imaging to mobile devices. With 35 employees, Spectricity has offices in Belgium, the USA, Taipei and Malaysia.

The S1 is currently under evaluation by major smartphone makers. As of January 2023, EVKs are available for device manufacturers driving large volumes.