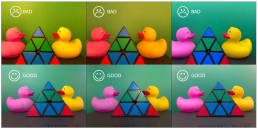

摩羯News|首次亮相,被投企业Spectricity在拉斯维加斯CES上展出首款配备多光谱成像相机的智能手机,以真实的色彩看世界

树立新标杆:Spectricity在拉斯维加斯CES展示突破性的智能手机摄像头配色技术

拉斯维加斯,1月8日 – 多光谱成像解决方案提供商 Spectricity 展示了其突破性的色彩匹配技术,将第一台多光谱相机集成到智能手机中,使得智能手机照片具有“真实色彩”。

小标题:突破,在智能手机中集成多光谱相机

长久以来,我们很多人都对智能手机无法重现我们看到的真实颜色而感到失望。我们的手机无法真实捕捉那令人惊叹的日落,颜料样品的色差,抑或是年华书写的皱纹 。因为智能手机本质上是“色盲”的,自动白平衡错误估计了白点。令人激动的是,Spectricity多光谱相机解决了这个问题,赋予手机相机真实视觉。智能手机无法准确还原色彩的年代过去了。

小标题:真实,还原比肉眼更准确的色彩

Spectricity的关键技术是其革命性的“S1”多光谱相机,它提供了准确色彩再现所需的全部信息。S1测量相机每个像素中 16 个波长的光谱,以便更好地评估白点,从而提供真实色彩。不仅如此,相机还可以比肉眼更准确地评估颜色,还原从油漆到肤色等所有内容的真实色彩表现。从此,手机成像色彩再无争议,所见即所得 。

小标题:信心,全球普及指日可待

提供一致的颜色是业界公认的问题。由于摄影和相机功能是智能手机升级的主要驱动力,Spectricity的创新引发了大量的兴趣,有潜力在不久的将来出现在每部智能手机中。目前,几乎所有主要的智能手机制造商都在进行技术测试,可以期待它将对消费设备行业产生重大的商业影响。

小标题:未来,有色彩的地方即是蓝海

值得一提的是,它的应用超越了单纯的美学,而渗透到各种实用场景。在电商领域,可以准确识别在线货品的颜色,无论是粉底,口红还是染发剂,也可以评估真实肤色和状态,以便客户更好的选品。在医疗领域也有深远的可能性,比如改善疾病的在线跟踪和提供健康建议。

Spectricity首席执行官Vincent Mouret评论道:“这款相机为实验室仪器和手机带来了前所未有的色彩准确性。在大多数情况下,用肉眼无法将检测到的颜色与真实颜色区分开来。现在您的图片终于可以保持色彩一致,您可以使用手机测量和保存物体或皮肤的真实颜色。这为远程个性化化妆品和零售场景打开了电子商务的大门。

Spectricity首席技术官Jonathan Borremans补充道:“所有智能手机供应商都承认问题确实存在,并正在努力解决。Spectricity的技术和解决方案处于行业顶尖地位。到 2026 年,这些光谱相机有望成为每部手机的标配,正如 Yole Development 所预测的那样。

Yole Development 是一家领先的市场研究、技术和战略分析公司。

关于Spectricity

Spectricity 成立于 2018 年,并得到了国际风险投资公司的支持,旨在将光谱成像引入移动设备。Spectricity 拥有 35 名员工,在比利时、美国、台北、上海和马来西亚设有办事处。

S1目前正在接受主要智能手机制造商的评估。Spectricity可为设备制造商的大批量生产提供EVK。

Field Application Engineer China

Location: China

Your main responsibilities will be to

- Define and build complex image sensor and camera test systems, together with our system engineers.

- Define our sensors and cameras:

- Define the right metrics and measure performance, analyse and document the results.

- Investigate complex optical properties and data analysis to improve efficiency.

- Learn and understand the Spectricity proprietary filter technology to interpret the obtained measurement results.

- Technically support the customers and partners in Asia. You will be the technical interface to the Belgium-based R&D

teams:- Provide proactive technical support, problem solving and Q&A for clients and partners to drive for design-

win and customer satisfaction. - Define and establish required documentation, training materials, agenda and conduct technical training.

- Participate in and facilitate failure analysis and corrective actions.

- Provide proactive technical support, problem solving and Q&A for clients and partners to drive for design-

- Support BD and Marketing to help define the customer and product requirements

- Attend trade shows and industry events when needed

- Conduct product demonstrations

- Discuss with prospective customers what they need in terms of product specifications, link the customer

application to our product specifications

- Support the operations team

- Visit and interface with Asia-based suppliers

Your profile, skills and talents

Ideally you are a creative, self-dependent engineer, highly-motivated to be part of a dynamic team creating new value, continuously and actively seeking better solutions for our problems. Specifically:

Specifically:

- You have a bachelor’s or master’s degree in engineering with at least 5 years of relevant experience, or similar

relevant degree by proven experience - You have proven experience with image sensors or camera products, and a good understanding of elementary

electronics and optics, boards and systems architecture - You understand industry trends, system architecture, block diagram and client roadmaps & client’s needs.

- You are very fluent in English and Chinese/Mandarin, and have good presentation skills

- You are willing to travel to Europe often

You have the perfect background if:

- You have experience with smartphone camera integration

- You have experience with Automatic White Balance algorithms and their implementations on SoCs

- You are well versed in image color and recoloring pipeline

You will help us be successful when:

- You have excellent communication skills both towards clients as internal stakeholders

- You are independent and proactive and are able to work well autonomously in a remote team

- You are a good team player, able to pursue and find compromise through constructive discussion, enthusiasm and

skills - You are result-driven, you have a natural desire to analyze and solve problems and you are self-critical

Spectricity推出了移动设备S1相机模块的真实色彩

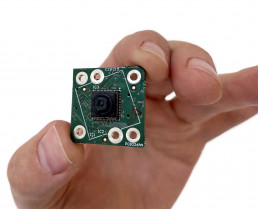

西班牙巴塞罗那,2023年2月27日 – 在推出S1(第一款通过智能手机相机提供真实色彩的传感器)后,Spectricity现在推出了使用这一尖端技术的微型相机模块。这是将上个月在CES上推出的首款微型移动设备多光谱图像传感器模组化,是一项开创性的新技术。预计将在未来几年所有智能手机均采用这项技术。

在巴塞罗那举行的世界移动通信大会(MWC)上发布的 新相机模块,将S1图像传感器与用于光谱成像的优化定制微型镜头集成在一个紧凑的模块中。由于其外形确实小巧,相机模块与移动设备和智能手机集成兼容。

Spectrity还宣布与大容量相机模块制造商Namuga建立合作关系。 Namuga的首席执行官Tae Youn Won 表示:“我们非常高兴能与Spectricity合作,开发和制造配备S1传感器的新一代相机模块。如果不分享日常内容,人们无法想象当今的现代个人生活。现在,Spectricity在色彩保真度方面的改进,再加上Namuga在制造和开发模块方面的经验,这可以提升到一个新的水平。”

Spectrity的首席执行官 Vincent Mouret表示,Spectrity很高兴与Namuga合作:“我们很高兴能与Namuga经验丰富的团队合作开发这一大批量产品。大容量相机模块对于移动设备集成是必不可少的。我们预计最快将于2024年发布第一款配备S1的智能手机,未来几年内所有智能手机都将采用我们的技术。”

智能手机相机将不再是色盲

S1光谱图像传感器解决了智能手机相机的色彩保真度问题,且可以通过物体的光谱特征来测量真实色彩。

S1在最近一届CES上被认为是一项技术突破:它是第一款 真正小型、可大量生产的 移动光谱图像传感器。此外,S1 能够以移动应用程序所需的视频速率捕获全可见光和近红外光谱范围。S1适合作为智能手机主相机的配套传感器。

首席技术官Jonathan Borremans表示:“S1相机模块标志着市场上任何多光谱相机的又一显著进步。到目前为止,还没有人能够将这些设备安装到微型模块中。S1可以集成到任何移动设备中。”

光谱成像将解决智能手机和用户设备相机色彩保真度差的问题。尽管图像传感器和相机技术取得了所有进步,但智能手机仍然无法捕获真实的颜色,因为智能手机受到三种颜色通道的限制:红色、绿色和蓝色。

Jonathan Borremans表示:“本质上,即使是高端智能手机,其照相机也“色盲”。S1 使用更丰富的光谱特征数据,能够大幅提高照片的色彩保真度。我们坚信,光谱成像将成为包括相机在内的所有设备的必需品。”

作为未来智能手机相机的组成部分,S1光谱相机传感器将推动个性化化妆品、卫生与健康、电子商务、智能园艺和认证等用户设备的创新。

关于Spectricity

Spectricity 成立于 2018 年,得到国际风险投资公司的支持,实现了光谱成像在移动设备中的整合。Spectrity在比利时、美国、台北和马来西亚均设有办事处。

S1 目前正在接受主要智能手机制造商的评估。设备制造商可采用评估套件进行导入批量生产的评估。

CES全球首发:Spectricity光谱照相机使智能手机照片的色彩更为真实

S1 光谱图像传感器为智能手机摄影制定了新的质量标准,为电子商务、化妆品、身份验证等领域注入新的能量

拉斯維加斯, 2023年1月4日—在 2023 年国际消费类电子产品博览会(CES)上,Spectricity 推出了 S1,第一款用于移动设备的多光谱图像传感器。预计到 2024 年将推出首批使用此类传感器的智能手机。两年内,这项技术有望应用于所有智能手机。

S1 光谱图像传感器解决了智能手机相机的色彩保真度问题,可以通过物体的光谱特征测量真实色彩。

S1 是一项技术突破:第一款真正小型化、可量产的移动光谱图像传感器。此外,S1 能够以移动应用程序所需的视频速率捕获全可见光和近红外光谱范围。非常适合用作智能手机主摄像头的配套传感器。

Spectricity 首席技术官 Jonathan Borremans:“S1 标志着市场上多光谱成像仪所取得的显着进展。迄今为止,还没有人将这些规格成功整合到微型芯片中。而 S1 可集成到任何移动设备中”。

目前,Spectricity 正在向多家智能手机制造商提供 S1 样品,将其包含在即将推出的型号中。

首席执行官 Vincent Mouret:“我们很高兴地宣布这一技术突破;第一款价格实惠的移动光谱成像仪。该产品的发布是 Spectricity 进军智能手机市场的重要里程碑,同时也是实现公司在移动设备中大规模采用光谱传感技术这一使命的重要里程碑。我们预计将于 2024 年发布首批配备 S1 的智能手机型号,未来几年内所有智能手机都会采用我们的技术”。

“RGB”:光谱成像如何提升智能手机色彩的真实度

光谱成像将解决智能手机和消费设备相机色彩保真度差的问题,而这也是造成照片色彩不准确以及肤色渲染不佳的根本原因。将提高拍摄技术的可靠性和包容性。

尽管图像传感器和拍摄技术取得了显著进步,但智能手机仍然无法捕捉到真实的色彩。受限于 3 个颜色通道(红、绿、蓝),自动白平衡(AWB)算法通常难以准确且正确地解析场景中的白点。结果可能无法得到正确的颜色。

首席技术官 Jonathan Borremans:“本质上,即使是高端智能手机,其照相机也“色盲”。S1 使用更丰富的光谱特征数据,能够大幅提高照片的色彩保真度。我们相信光谱成像将成为包括照相机在内的所有设备的重要组成部分”。

未来的智能手机相机:S1 将推动消费设备的创新

S1 将对消费设备行业产生重大商业影响:

- 研究表明摄影和拍摄功能是智能手机更新换代的主要驱动力

- 个性化化妆品的市场规模已经达到 400 亿美元。光谱成像将推动从零售模式到家庭的转型,为您的移动设备提供专家建议,通过采用该类别提升客户满意度。

- 医疗:光谱成像将解锁相关应用和用例

- 电子商务:更好的显色性将为在线商务提供有力支持

- 为身份验证(面容 ID)甚至智能园艺的新应用和用例赋能

关于Specricity

Spectricity 成立于 2018 年,得到国际风险投资公司的支持,实现了光谱成像在移动设备中的整合。Spectricity 拥有 35 名员工,在比利时、美国、台北和马来西亚设有办事处。

S1 目前正在接受主要智能手机制造商的评估。自 2023 年 1 月起,EVK 可供大批量生产的设备制造商使用。

Spectricity 获得 Flanders Innovation & Entrepreneurship (Agentschap Innoveren & Ondernemen - VLAIO) 的 300 万欧元拨款,以协助 Spectricity 开发为移动设备设计的光谱成像传感芯片。

Spectricity 获得 Flanders Innovation & Entrepreneurship (Agentschap Innoveren & Ondernemen - VLAIO) 的 300 万欧元拨款,以协助 Spectricity 开发为移动设备设计的光谱成像传感芯片。 VLAIO 致力于推广佛兰德斯的创新,并资助佛兰德斯创业公司的研发。

Spectricity 首席执行官 Vincent Mouret 表示:

“Flanders Innovation & Entrepreneurship 自始就支持 Spectricity,并在我们的研发轨迹中发挥了重要作用。 新的VLAIO 拨款将帮助我们加快针对智能手机市场的先进消费类相机模块和人工

Spectricity 在 X-FAB 部署专有技术,为移动设备带 来光谱成像功能

实现在 CMOS 图像传感器上集成小型像素化光谱滤波器

中国北京,2022 年 6 月 29 日——全球公认的卓越的模拟/混合信号晶圆代

工厂 X-FAB Silicon Foundries(“X-FAB”)今日宣布,与专注多光谱成像技术研

发的半导体设计公司 Spectricity 携手,推出独特成像解决方案。来自 Spectricity

的专有光谱成像技术已部署在 X-FAB 工艺平台的量产设备中;此举将首次实现移

动设备光谱图像传感器的低成本制造。

Spectricity 的专利光谱传感器解决方案将小型像素化的光谱滤波器集成至可

见和近红外光谱范围的 CMOS 图像传感器上,可包含 16 个或更多的高质量窄带

通道。通过此次部署,X-FAB 成为唯一能够批量生产如此小尺寸光谱像素 CMOS

的代工厂,使其和 Spectricity 能够更好地满足移动手持设备 OEM 的需求。由此

带来的解决方案凭借紧凑性和高光谱密度提供了高空间和光谱分辨率感知功能,

助力厂商把握智能手机、物联网、医疗保健和可穿戴设备等领域的机遇。

将光谱相机模块整合至移动设备,贴合了目前增加先进传感功能的持续趋

势。光谱成像仪将能够捕捉多个光谱通道的图像数据,超越传统的红、绿、蓝颜

色通道,并将允许测量物体的光谱特征。需要更为精确自动白平衡的应用,如图

像采集、个性化的化妆品和护肤品、远程医疗及智能园艺/农业等,将会由此受

益。

Spectricity 首席执行官 Vincent Mouret 表示:“我们将最初由 imec 开创的

前沿技术,成功部署至 X-FAB 量产设备中,是 Spectricity 在服务全球智能手机市

场征程中的一个关键里程碑,这也使得我们与实现推动在移动设备中大规模采用

光谱传感的目标更接近。”

X-FAB 首席技术官 Jörg Doblaski 评论说:“Spectricity 团队的工程专业技能

给我们留下深刻的印象;我们对与一家创新的欧洲企业成功合作实现光谱成像仪

产品而感到十分兴奋。其技术转让已在很短时间内完成,最初的批次也已达到所

需规格。”

Spectricity 计划于 2022 年晚些时候开始推出其由 X-FAB 制造的光谱成像解

决方案样片。

缩略语:

CMOS 互补金属氧化物半导体

IoT 物联网

NIR 近红外线

OEM 原始设备制造商

关于 X-FAB:

X-FAB 是领先的模拟/混合信号和 MEMS 晶圆代工集团,生产用于汽车、工业、消

费、医疗和其它应用的硅晶圆。X-FAB 采用尺寸范围从 1.0μm 至 130nm 的模块化

CMOS 和 SOI 工艺,及其特色 SiC 与微机电系统(MEMS)长寿命工艺,为全球客户打

造最高的质量标准、卓越的制造工艺和创新的解决方案。X-FAB 的模拟数字集成电路

(混合信号 IC)、传感器 MEMS 在德国、法国、马来西亚和美国的六家生产基地生产,

并在全球拥有约 4,000 名员工。www.xfab.com

关于 Spectricity:

Spectricity 是一家总部设在比利时的无晶圆厂公司,其利用 CMOS 技术开发和制造

光谱传感解决方案。这些解决方案专为大批量生产而设计,主要面向消费和移动设备。

公司于 2018 年成立,并得到风险投资的支持。其技术建立在 imec 独家授权的专利组合

基础之上;其中,imec 作为世界领先的纳米电子和数字技术研发与创新中心,其所推动

的技术和产品凝聚了超过 15 年的研究与开发成果。更多信息,请访问:

spectricity.com。